GC-MS

Cost-Effective Solutions for Nitrosamine Testing

Jul 23 2024

Pharmaceutical manufacturers face challenges in ensuring product safety and quality, especially in detecting nitrosamines, harmful contaminants. Accurate and efficient detection of nitrosamines is crucial but requires substantial resources. As a result, many companies outsource their testing to specialised laboratories, leading to longer turnaround times and less control over the process.

Gas Chromatography-Tandem Mass Spectrometry (GC-MS/MS) is a common method for detecting nitrosamines in pharmaceuticals. This technique combines gas chromatography with mass spectrometry to identify and quantify trace levels of nitrosamines. However, in complex pharmaceutical matrices, GC-MS/MS can struggle with selectivity. This makes it difficult to distinguish nitrosamines from other compounds and background contaminants. Such challenges may delay product release, affecting a company's costs and reputation.

Selectivity in nitrosamine testing is crucial because it directly influences the accuracy and reliability of results. In the pharmaceutical industry, products must be free from harmful contaminants like nitrosamines for regulatory compliance and patient safety. High selectivity in testing methods enables companies to accurately identify and quantify nitrosamines, even among other compounds, avoiding false negatives and ensuring no harmful levels of nitrosamines are overlooked.

High sensitivity in testing methods is essential for detecting even trace amounts of nitrosamines, helping prevent false alarms and missed detections. This reliability is crucial for maintaining product quality, meeting regulatory standards, and avoiding costly delays and additional testing. Therefore, a testing method with high selectivity, such as Ellutia’s 800 series Thermal Energy Analyser (TEA), is crucial for optimising production efficiency, ensuring product safety, and maintaining regulatory compliance.

The operational costs of GC-MS/MS systems are significant, requiring substantial investments in purchase, maintenance, and operator training. The extensive sample preparation required for GC-MS/MS also adds to the costs and prolongs turnaround times, straining financial resources and potentially leading to higher product prices or budget cuts in other areas. This complexity also reduces the reproducibility of results and increases the likelihood of errors, affecting the reliability of the quality control process and slowing down production timelines.

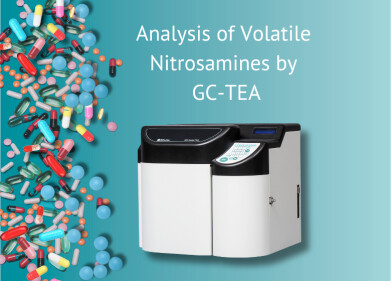

GC-TEA offers a cost-effective alternative with simpler operation, reduced maintenance needs, and minimal background interference. By streamlining sample preparation, typically involving methanol extraction, centrifugation, and filtration, GC-TEA improves reproducibility and reliability, enabling pharmaceutical companies to maintain consistent quality standards more effectively. This efficiency allows companies to better allocate resources and invest in critical areas such as innovative research and development, enhancing their competitive edge. Moreover, GC-TEA is designed to interface seamlessly with most GC systems, making its integration into existing laboratory setups straightforward and efficient.

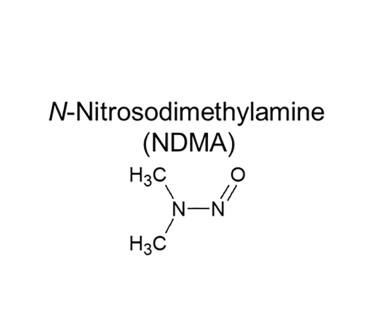

In practical applications, GC-TEA has proven effective in detecting nitrosamines, such as NDMA, in products like Metformin, Ranitidine, and Sartan tablets. Its ability to analyse different sample sizes and identify nitrosamine distribution variability within tablets makes it a versatile and reliable option. This versatility helps ensure compliance with safety standards and improves overall quality control processes.

Pharmaceutical companies using GC-MS/MS for nitrosamine detection face challenges related to method development, sensitivity, operational costs, and sample preparation complexity. While GC-MS/MS is effective, GC-TEA addresses these challenges by providing higher selectivity, minimal background interference, lower operational costs, and simpler sample preparation. Integrating GC-TEA into testing protocols can enhance the reliability and efficiency of nitrosamine detection, ensuring the safety and quality of pharmaceutical products and helping companies meet regulatory requirements more effectively.

Watch our latest webinar on Analysis of Volatile Nitrosamines by GC_TEA.

Join our next nitrosamine webinar on the 15th August 2024 at 3pm UK time to find out how the Automated Total Nitrosamine Analyser fits in with Nitrosamine testing.

Events

Apr 27 2025 Portland, OR, USA

May 11 2025 Vienna, Austria

May 18 2025 Tempe. AZ, USA

May 21 2025 Birmingham, UK

Jun 01 2025 Baltimore, MD, USA