-

Figure 1: High DBC for High Loadability Picture caption: Comparison Study: DBC values of three resins for proteins with different sizes and characteristics.

Figure 1: High DBC for High Loadability Picture caption: Comparison Study: DBC values of three resins for proteins with different sizes and characteristics. -

Figure 2: High DBC at High Flow Rates Picture caption: Determination of DBC values of three resins at different linear velocities

Figure 2: High DBC at High Flow Rates Picture caption: Determination of DBC values of three resins at different linear velocities

Equipment

What makes the dynamic binding capacity so important?

Nov 21 2023

High productivity is the main focus when a chromatography resin is selected in downstream processing (DSP). The higher the dynamic binding capacity (DBC) of a resin, the more substances can be loaded onto the column and consequently the higher is the throughput of the process. The DBC is a real process parameter as it is determined using the chromatographic setup. Therefore, modern process resins with maximum DBC are needed for increased productivity.

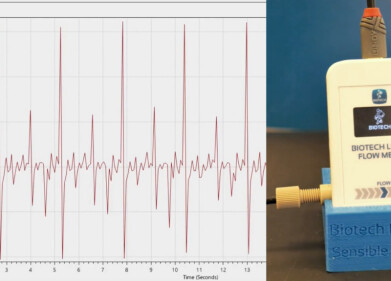

How to Determine the DBC of a Resin

To determine the DBC, a protein solution with a defined concentration is pumped through the column and the proteins bind to the column. The solution is pumped until a flow through of the protein is detected and saturation is reached. Afterwards, the amount of protein that was pumped through the column until a protein breakthrough at 10 % of the saturation is calculated. This value for the binding capacity can be normalised on the resin volume: DBC = mg bound protein/mL resin

High DBC for High Loadability

The higher the DBC of a resin for a dedicated protein or antibody, the higher is the throughput. This of course depends on the target molecule and the mobile phase composition. Therefore, resins that exhibit high DBC values for various targets are needed for efficient DSP. In a comparison study, the DBC values of proteins with different sizes and characteristics were determined with three IEX materials. The results show impressively: BioPro IEX SmartSep shows higher dynamic binding capacity for both, small peptides, and large proteins.

High DBC at High Flow Rates

The DBC depends on the chromatographic parameters such as pH, buffer conditions, conductivity and also on the flow rate. In an example, the DBC values of three resins were determined at different linear velocities. The result: BioPro IEX SmartSep shows high loadability even at high flow rates.

High flow rates further improve the productivity of the purification because they additionally increase the throughput. Therefore, a combination of high loadings and high velocities are ideal for efficient processing. BioPro IEX combines both – high loadability and high flow rates.

Conclusion

The dynamic binding capacity is an essential factor to increase the productivity of downstream processes. The higher the binding capacity, the higher is the maximum loadability of the target feed which consequently increases the throughput. The DBC can be determined by loading the target onto the column and measuring its breakthrough. The IEX resins from YMC BioPro IEX exhibit high DBC values for various types of biomolecules – from small peptides to large proteins and antibodies – even at elevated flow rates. In a direct comparison of the specified DBC values, the resins from YMC clearly outperform alternative resins used for process scale.

Please find more information about the importance of DBC for DSP in our Technical Note or contact us directly.

Events

May 11 2025 Vienna, Austria

May 18 2025 Tempe. AZ, USA

May 21 2025 Birmingham, UK

Jun 01 2025 Baltimore, MD, USA

Jun 15 2025 Bruges, Belgium