Columns (LC)

Successful LC separations on pilot scale

Feb 21 2023

The aim of a LC separation on pilot scale is to purify as much product as possible in as short a time as possible as cheaply as possible. An optimum yield is achieved with a high column performance of the packed column. This requires the column bed to be packed efficiently and homogenously. Therefore, the selection of suitable column hardware is an essential aspect. Packing, qualifying, and operating as well as unpacking the column all take time and reflect in the overall process costs. Optimised column hardware offers possible savings by reducing the overall costs of the process.

During the design of the YMC PilotPLUS columns, YMC specifically focussed on the handling during the packing and unpacking steps. As a result, packing procedures can be improved and the efficiency can be increased.

Special requirements for the column hardware

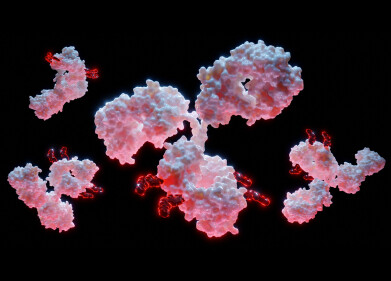

Glass pilot columns such as the YMC PilotPLUS columns are mainly used for BioLC applications and packed with soft gels. This application area makes additional demands on the column hardware because compounds such as peptides, proteins, oligonucleotides or antibodies can have very complex three-dimensional structures, which can be distorted by metal ions. Therefore, metal free wetted parts of the hardware are essential.

With no metal present, the YMC PilotPLUS columns are the perfect match for BioLC applications. All wetted parts are in compliance with FDA, BES/TSE and USP Class VI regulations. Certification and full documentation are available for validation purposes.

Fast piston insertion without air bubbles

Pilot columns are most frequently packed by means of slurry packing methods. In this case, it is very important to initiate the packing process as quickly as possible. Therefore, the following steps need to be performed without delays.

- The gel needs to be transferred quickly into the column body without introduction of air.

- The piston needs to be inserted without delay, as the packing pressure needs to be applied as soon as possible.

During the slurry filling introduction of excessive air bubbles needs to be avoided. Therefore, filling has to be done carefully and slowly, but with minimum delay.

The YMC PilotPLUS columns are the solution for fast and bubble-free piston insertion. Through an inclined surface at the glass body and the drain function, the piston can be inserted into the solvent. Excessive solvent can flow away through the drain function. For prevention of air bubbles during pouring in the slurry, a special column filling tool is available.

Pilot column for routine application

If columns in a process require to be used routinely and the packing material has to be changed often, safe and easy handling is of special interest. For an efficient overall process, not only the column packing but also the unpacking for routine applications must be fast. The key to a fast packing and unpacking is a removable column body which is easy to unlock via three locking bolts and repositioning in the upside-down position.

Events

Apr 22 2025 Kintex, South Korea

Analytica Anacon India & IndiaLabExpo

Apr 23 2025 Mumbai, India

Apr 27 2025 Portland, OR, USA

May 11 2025 Vienna, Austria

May 18 2025 Tempe. AZ, USA