Columns (LC)

How Multi-Column Chromatography Improves Downstream Processing and Saves Money

Jul 26 2022

One of the most time-consuming and resource-consuming parts of every bioprocess is downstream processing, particularly at the capture step. The traditional capture chromatography method for processing (single-column approach) requires a lot of time, equipment, and resin, keeping costs high and resulting in production bottlenecks in a very time-sensitive industry.

With the BioSMB multi-column chromatography platform you can get the best of both worlds. It offers significant savings without sacrificing any of the quality you expect, using essentially the same process in a more efficient way.

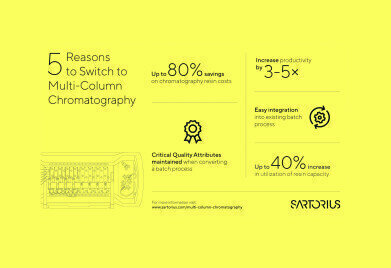

Multi-column chromatography (MCC) is currently one of the leading routes to optimize the downstream capture steps. Here are just a few reasons why you should start using MCC today:

1: Reduce Waste and Cut Costs

Manufacturing companies throughout the world have a common goal: relentlessly eliminate waste to create the most efficient process. In downstream processing the resin represents a significant portion of the costs for single-column chromatography batch processes. However, at any given time with a single-column approach, only a small amount of the resin in the column is actually doing its job. The rest sits idle without being fully utilized and is eventually thrown away.

A better alternative is multi-column chromatography, which uses multiple small columns. These columns are cycled much more frequently utilizing the resin fully. When you do more with less you can achieve up to 80% savings on chromatography resin costs with MCC. The MCC system is a direct replacement for a single column system.

2: Eliminate Bottlenecks:

Single-column chromatography facilities often limit throughput because using more resin to speed up the process costs more. Using less resin saves money, but it slows down the process and creates a bottleneck.

With multi-column chromatography each column is fully loaded, then once it’s complete that column can begin the purification process, which continues with each column cycling through various different stages in parallel. You get a more efficient process by performing multiple steps at the same time and increase productivity by 3-5x over single-column chromatography.

3: Maintain Quality Attributes and Performance

Facilities still using single-column chromatography might wonder whether making these changes to the process would negatively impact quality. The switch from the standard large single column to multiple smaller columns is different, and the concept of column overload is new in most facilities. But neither will negatively impact quality attributes, so you get the same quality with more efficiency, all while reducing costs.

4: Avoid Adding More Hardware

The MCC system enables the use of much smaller columns. You can configure as many or as few columns as needed to optimize your manufacturing process. But the size burden is always less, as is the storage and packing overhead. MCC systems eliminate the need for costly and large ancillary hardware traditionally required with conventional single-column approaches.

Learn more about how MCC works in downstream processing and talk to the Sartorius team about how this innovative method could improve your pharmaceutical manufacturing processes.

Events

May 11 2025 Vienna, Austria

May 18 2025 Tempe. AZ, USA

May 21 2025 Birmingham, UK

Jun 01 2025 Baltimore, MD, USA

Jun 15 2025 Bruges, Belgium