Bioanalytical

Glass columns as fixed bed reactors for immobilised enzymes

Jun 22 2021

In a recent study, YMC glass columns have been used as fixed bed reactors for immobilised enzymes. For immobilisation, a solid support (mesoporous silica, SBA-15) is used and the enzyme is linked to this surface via adsorption. This way, the high selectivity of enzymes can be used for industrial processes, as the stability is protected by the enzyme layer.

Immobilisation in fixed bed vs. batch

The scope of the study was the evaluation of the enzymatic activity of an immobilised β-glucosidase from almonds (130 kDa). J.M. Gómez et al. compared two immobilisation techniques:

- Immobilisation in a fixed bed column

- Immobilisation in batch.

The immobilisation in a fixed bed was carried out in an ECOplus glass column with 5 mm ID and 250 mm length. As a solid support, SBA-15 was packed into the column. The enzyme solution was pumped through the column with a flow rate of 0.3 mL/min. The enzyme concentration and the catalytic activity at the column outlet were measured continuously.

For immobilisation in batch, the β-glucosidase was added to the SBA-15 suspension in Eppendorf tubes.

Excellent adsorption in a fixed bed glass column

J.M. Gómez et. al. showed, that the immobilisation in a fixed bed glass column gives excellent results with regards to:

- 1. Increased adsorption capacity:

- 3.5 times greater adsorption compared to batch due to applied pressure

- 2. Catalytic activity in continuous process:

- 100% substrate conversion

- 3. High activity level:

- Continuous process worked for more than 10 h without deactivation of the enzyme

- 4. Strong immobilisation:

- Only 7% of leaching in the washing step

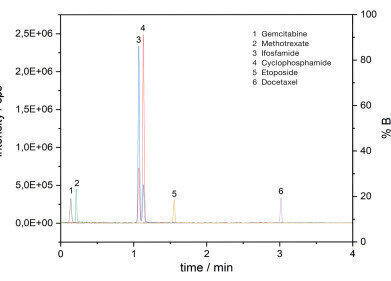

You want to see the chromatographic results? Check out the Technical Note here!

Events

Apr 22 2025 Kintex, South Korea

Analytica Anacon India & IndiaLabExpo

Apr 23 2025 Mumbai, India

Apr 27 2025 Portland, OR, USA

May 11 2025 Vienna, Austria

May 18 2025 Tempe. AZ, USA