Equipment

Custom degassing solution for automated flow chemistry

Jan 17 2024

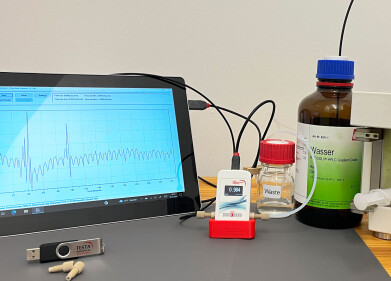

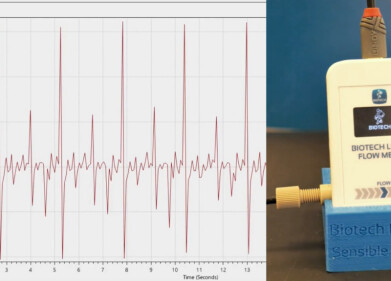

Biotech Fluidics highlights the creation of a customised 8-channel DEGASi® Plus inline degassing system tailored for AutoSyn AB, a start-up specialising in flow chemistry and continuous processing systems.

Recognising the limitations of off-the-shelf solutions for the specific requirements of AutoSyn's advanced flow chemistry system, Biotech Fluidics addressed the challenge by developing a bespoke degasser. In response to space constraints and the need for a positive nitrogen pressure to prevent cavitation, Biotech Fluidics engineered a specialised 8-channel degasser to simultaneously degas eight different solvents. This application-optimised degasser seamlessly integrated with the AutoSyn flow chemistry system within a few weeks of conception.

AutoSyn AB, specialising in the automation of chemical development, utilises the Autonomous Chemistry Lab flow chemistry system to expedite chemical reactions and achieve a transition to greener and more sustainable products. Hannes Schomaker, co-founder and CTO of AutoSyn AB, commended Biotech Fluidics for their expertise in degassing technology and their ability to quickly produce a degassing system tailored to their needs. The resulting 8-channel DEGASi® Plus module exceeded expectations in terms of build quality, degassing performance, and reliability.

Biotech Fluidics, renowned internationally for high-performance degassing systems, offers standard degassers with up to six channels. The introduction of the DEGASi® PLUS series has set a benchmark for vacuum degassers. These systems, equipped for a wide range of applications, save time and money by preventing production disruptions caused by bubbles in fluidic lines.

Learn about the Autonomous Chemistry Lab system.

More information online

Events

May 11 2025 Vienna, Austria

May 18 2025 Tempe. AZ, USA

May 21 2025 Birmingham, UK

Jun 01 2025 Baltimore, MD, USA

Jun 15 2025 Bruges, Belgium