Autosamplers

What is Peak Tailing?

Aug 08 2014

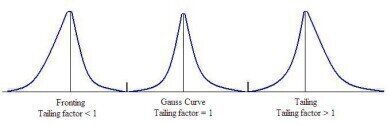

An ideal chromatography peak is a nice sharp symmetrical shape, a Gaussian peak, on a flat baseline. A peak can deviate from this ideal in several different ways. It can become asymmetrical, flatten and become broader, or the baseline can rise.

One of the common shifts away from a Gaussian peak is when the back half of the peak falls away. If the peak were split into two, vertically, the later half would be wider than the first half of the peak. This effect is most clearly seen close to the baseline and is known as peak tailing.

Quantifying Peak Tailing

It is very difficult to remove all of the tailing from a peak, even for new columns. The quality of separation and the analytical data can be affected by tailing. Consequently, if tailing is quantified, it is possible to place an acceptable limit on the amount a peak can tail.

There are two main methods for defining peak tailing:

- Tailing factor (Tf) – widely used in the pharmaceutical industry.

Let a and b be the peak half-widths at 5% of the peak height, a is the front half-width, b is the back.

Tf = (a + b) / 2a

- Asymmetry factor (As) – used in most other industries.

As in Tf, a and b are the peak half-widths, but at 10% of the peak height.

As = b / a

Either method of measuring tailing can be used – unless it is defined in a method or standard – but note the methods are not interchangeable.

Acceptable Tailing

Since most columns exhibit some peak tailing, what is considered an acceptable As value?

A new column is considered acceptable if the As value is 0.9 - 1.2 (0.9 indicates slight fronting).

In practical terms, an As value below 1.5 is usually OK to work with, and up to As = 2.0 may be acceptable depending on the separation and resolution of the peaks.

If the As value is greater than 2.0, then there is a problem that needs to be identified and fixed.

Peak Problems

Two of the analytical issues as a result of peak tailing are:

- Peaks with a large As value might have a significantly reduced peak height. This affects the analysis when wide ranges of different concentrations of chemicals are being detected.

- Data analysis systems might not accurately assign the end of a peak, so the peak area is mis-calculated.

Stop Tailing at the Start

There are many possible causes of peak tailing and many different fixes.

Elimination of peak tailing should start during method development, when the selection of the correct column and instrument parameters is made.

If tailing starts suddenly it can be an indication of an instrument or column problem, or even something as simple as overloading the column with a poor injection.

An indication of how peak shape can influence method development can be found in the article: Correlation of Analyte Retention in Organic and Inorganic Mobile Phases to aid Liquid Chromatography Method Development.

Image Source

Events

May 11 2025 Vienna, Austria

May 18 2025 Tempe. AZ, USA

May 21 2025 Birmingham, UK

Jun 01 2025 Baltimore, MD, USA

Jun 15 2025 Bruges, Belgium